Summary

At some stage in any business’s growth cycle, it will need logistical support to meet its expansion objectives. When seeking logistical support, a business can partner with a third-party or fourth-party logistics provider. There is the option of managing logistics in-house as opposed to partnering with an outside vendor, and both choices can be analyzed through a cost and efficiency analysis as applied to the company’s current business model.

3PL will require coordination across a specific set of parties, including the primary business producing a product, the logistical provider, and the different carriers it employs. With 3PL logistical support, a business retains overall management of the process and uses an outside provider to outsource the transportation and logistics aspects.

A 4PL, or lead logistics, model represents a higher level of supply chain management as compared to the 3PL model. A 4PL acts as a single coordinating point for a business and includes procurement, materials planning, logistics, inventory management, finance management, packaging, warehousing, and delivery and returns. Contrasted with a 3PL, a 4PL offers more strategic insight, management logistics, and execution across the entire supply chain.

Both models offer different advantages and disadvantages, and businesses are advised to consider their inventories, order volumes, specificity of the product, and degree of third-party involvement before they decide which option best serves their needs.

INDEX

- Third-Party Logistics

- Fourth-Party Logistics

- Differences Between A 3pl And 4pl Vendor

- Choosing The Right Model For Your Business

- Industry Examples – 3pl Vs 4pl

What Are Your Logistics Outsourcing Options?

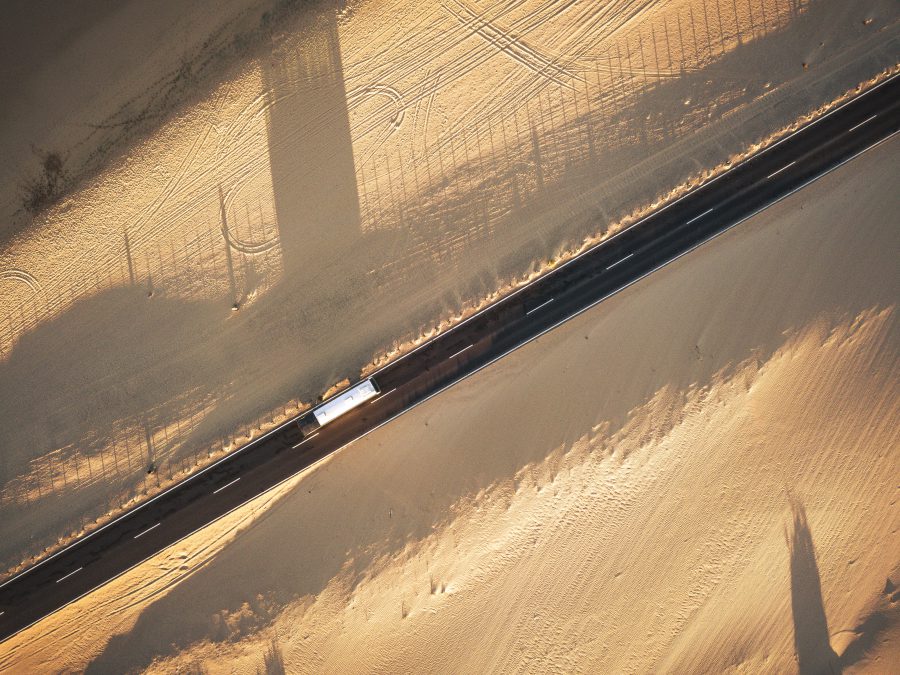

Organized logistics are the key to successful business growth, which requires supply chains that can meet pressing customer demands, show agility and demonstrate innovation in an ever-changing environment. To meet these objectives, keep pace with customer demands, and outperform competitors, requires implementing seamless logistics.

Choosing The Right Logistics Vendor Model For Your Business

Before deciding on a logistics partner, you need to ask yourself how much control you want to retain over how your product is assembled and delivered.

This question must be weighed against the amount of investment you are willing to commit to scaling your business. If a company is having a difficult time coordinating along its supply chain or is losing precious time and resources in this process, it should outsource.

When it comes to logistics, many businesses find that outsourcing to a logistics partner is the most cost-efficient approach. Both third-party logistics providers (3PL) and fourth-party logistics providers (4PL) can offer logistics support for a growing business, but they tend to cater to specific sectors with different service parameters and oversight.

But what, exactly, are the benefits and drawbacks of 3PLs and 4PLs?

Third-Party Logistics

In a 3PL model, a business maintains overall management and only outsources the transportation and logistics to a provider. The 3PL provider may assist with additional warehousing services, such as crating, boxing, and packaging, to add more value to the supply chain.

A 3PL supply chain model is simpler and coordinates across three broad parties:

- A business

- A logistics provider (packaging, warehousing, and inventory management)

- A carrier

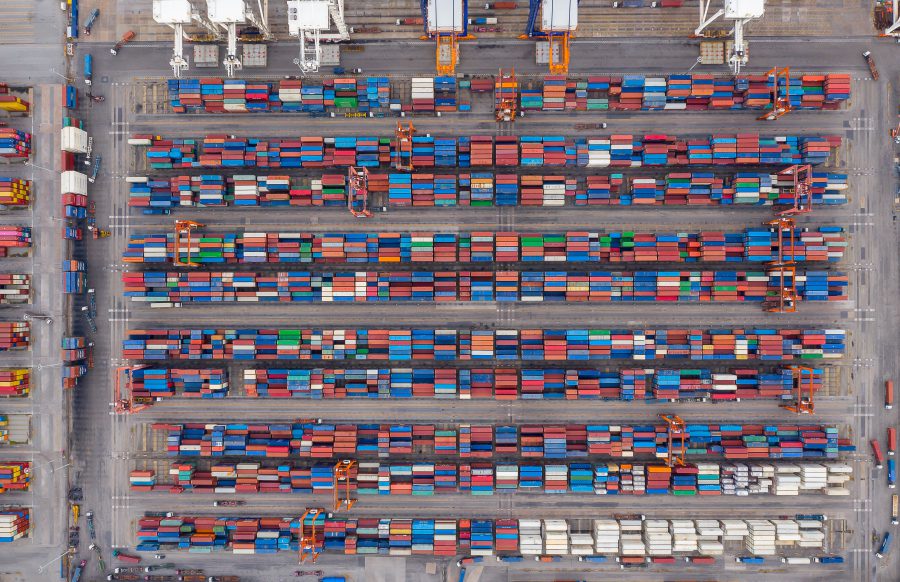

With 3PL, a business oversees its supply chain. The 3PL provider does not take ownership of the products being shipped, but only facilitates their movement from supplier to manufacturers, as well as finished products from manufacturers to distributors and retailers.

3PL services include:

- Transportation

- Warehousing

- Cross-docking

- Inventory storage and management

- Picking and packaging

- Freight forwarding

- Customs brokerage and contact management

- IT solutions

Advantages of a 3PL

- For small businesses, a 3PL is usually the first point of logistical support when they enter their growth cycle. Ensuring delivery of a product, in addition to producing the product, is an expensive and time-consuming task for a business. Finding the right 3PL can save your business money through economies of scale. An SME can particularly benefit from outsourcing logistics to concentrate exclusively on production.

- Partnering with a 3PL is a faster way to move goods across greater distances, as businesses can benefit from speedier deliveries by utilizing multiple 3PL storage locations.

- 3PLs work well for a fast-growing business with rising order volumes by exploiting the provider’s scalability. Logistics can easily be scaled up or down without a company worrying too much about inventory and warehousing costs.

- A business still retains control over customer service and returns.

- As the model is decentralized, it reduces risk across the supply chain, but still allows for quick responsiveness to meet customer expectations.

Disadvantages of a 3PL

- A business has limited direct oversight and control over its inventory once it is secured by the 3PL provider.

- Ensuring quality control and customer service can become more difficult. Errors made by a 3PL vendor, such as slow delivery, may be attributed to the business rather than to the logistics provider.

- Finding a provider who you can trust and rely on, and who understands the specific needs of your business, can be a time-consuming task.

- 3PL providers can create a level of dependency, making it difficult to switch to another vendor. Equally, it is hard to move operations in-house if pricing and service levels no longer meet expectations.

- The cost-benefit could be lost if orders are low in volume.

- Generally, 3PLs are more suitable for small-to-medium business enterprises.

Fourth-Party Logistics

A 4PL, or lead logistics, model represents a higher level of supply chain management as compared to the 3PL model. Compared to a 3PL, a 4PL offers more strategic insight, management logistics, and execution across the supply chain.

With a 4PL, a business outsources its entire supply chain management, including procurement, materials planning, logistics, inventory management, finance management, packaging, warehousing, and delivery and returns.

Acting as a single coordinating body across all aspects of the supply chain and client organization, a 4PL provider may enter into a joint venture or long-term partnership with a primary business to manage the logistics for a specific location or lines of business.

Some of the services rendered by 4PLs include:

- Consultancy services that offer advice on how to streamline supply chains

- Freight sourcing strategies

- Logistics strategies

- Analysis and development of product-specific transportation routes

- Analysis of carrier performance

- Effective management of 3PLs, as typically 4PLs do not own transportation or warehousing assets, but instead, coordinate those aspects of the supply chain with other vendors

- Business planning and project management across supplies, demands, and timelines

- Management of inbound, outbound, and reverse logistics

- Proper coordination of a wide supplier base in various geographical locations

- Network analysis and designs

- Analysis of capacity utilization

- Proper inventory planning and management

Advantages of 4PLs

- Versatile, agile, and professional operational support

- As a single point of contact for all parties involved in the supply chain, outsources and coordinates all the logistical requirements of a business across different vendors

- Provides cost-effective supply chain solutions that improve profit margins

- Outsources all logistics to third-party professionals, letting manufacturers focus on their product

- A 4PL is objective in choosing suppliers, concentrating on finding the best combination of value and service, which is passed on to the client as a cost-benefit

- Typically, a 4PL employs more efficient, integrated technologies to deliver a higher level of visibility through the supply chain

Disadvantages of a 4PL

- A business has less direct control over fulfillment and logistics processes

- 4PL operations tend to be better suited for larger enterprises or smaller businesses with growth potential

Differences between a 3pl and 4pl vendor

In a 4PL model, manufacturers outsource both the organization and oversight of their supply chain. The 4PL can, in turn, manage the operations of multiple 3PLs to deliver overall more efficient supply lines.

To put it simply, a 4PL handles the entirety of a supply chain while a 3PL is mainly concerned with handling just the logistical processes.

The size, scale, and needs of an enterprise determine whether a 3PL or 4PL is right for your business. A business may end up working across both 3PL and 4PL vendors for different situations.

It becomes critical, therefore, to identify some key differences between the two to help companies decide which one option suits their current needs and plans for growth. Below are the key differences between 4PLs and 3PLs, directly compared to each other.

| 3PL | 4PL |

| A 3PL is usually better suited for small-to-medium businesses. | 4PLs are usually a better fit for large business models. |

| 3PLs focus more on daily operations. | 4PLs operate to optimize different lines of a supply chain to integrate functions better, including coordinating the activities of different 3PLs. |

| 3PLs tend to focus on one-off, linear methodologies. | 4PLs provide a more complicated level of coordinated logistics across multiple avenues, often operating simultaneously, and include managing inventory, timelines, and trend analysis, making them more efficient than 3PLs. |

| In a 3PL model, businesses often take care of certain aspects of the supply process themselves. | 4PLs operate as a single point of contact for a business’s supply chain. |

How Can You Decide If A 3pl Or 4pl Vendor Is Right For You?

When choosing between 3PL or 4PL vendors, a business should ask itself the following questions:

Where am I in my growth cycle?

Deciding whether to employ a 3PL or 4PL model depends on where a business stands in its growth cycle and how ambitiously it wants to scale.

For many businesses, partnering with a 3PL is the first step toward growth. One way to recognize that it’s time to onboard a 3PL provider is when order volumes and inventory control become too much to manage in-house.

However, as a business expands even further, it may also outgrow its in-house capacity to manage 3PL services. At this point, a 4PL can become the single point of coordination between subsidiary 3PLs, carriers, warehouse vendors, and other partners. A 4PL can integrate more advanced technology and resources for visibility and reach across a wider network.

How much control do I want to retain?

4PLs are more directly involved in a business’s operational components. The business relies on its data and input for major decisions. Additionally, as 4PLs usually enter into a long-term relationship with their clients, they have a bigger stake in how the business runs.

A 4PL is more accountable to the customer because it has “ownership” in the processes. For a business that values customer service as a part of its brand image, a 3PL may not be able to deliver the seamless quality of service across the entire customer journey that a 4PL can bring.

While a business relinquishes some direct control over how it runs end-to-end to a 4PL provider, partnering with one offers a business a source of expert feedback and insights. Having a professional 4PL partner means that an enterprise can focus on its product and services without worrying about other aspects of the business.

What are my cost advantages?

Most 4PLs have no assets to protect and are in a position to act exclusively on behalf of a client. With no margins on transportation, 4PLs can objectively offer controlled costs.

This position, combined with logistics sourcing (through subsidiary 3PLs), can lead to substantial savings for a business. By taking the weight of logistics off a company, businesses can focus more exclusively on expansion and growth.

Additionally, for some businesses, 3PLs may not be suited to carry their products. Generally, 3PLs do not have existing frameworks to handle flammable, hazardous, or perishable goods. Partnering with a logistics provider that can’t handle your product properly will be an expensive (and ineffective) proposition in the long run.

Industry Examples – 3PL Vs 4PL

Medical devices and supplies

- 3PLs work well across industries where visibility in the movement of goods is necessary. According to regulatory requirements in the healthcare sector, for example, medical devices and supplies need to be tracked at every step of the process with a verifiable chain of custody. 3PLs can track inventory across multiple locations and carriers through technology solutions. Equally, 3PLs can manage delivery, on-site inventorying, returns and repairs, and other small but vital steps in serving customers. By consolidating deliveries, a 3PL can help reduce costs significantly.

- However, in the face of natural disasters, global conflicts, resource shortages, or even pandemics, 3PL solutions may not be enough to cater to disrupted supply chains, last-minute orders, and multiple inventory requests. Equally, when it comes to the movement of perishable and hazardous medical goods, a 4PL partner may be better positioned to meet a business’s logistics needs because it can manage complex routing optimization, chain-of-custody requirements, and tight delivery schedules while reducing inventory costs.

Field services

- In increasingly competitive markets, businesses that supply and fit parts as part of their service contracts have had to significantly raise their game. Successful businesses are those that achieve this, reduce costs, and still add value to their customer proposition by paying special attention to aftersales service. Small and medium enterprises offering field service equipment and products can use 3PLs to quickly distribute products through spread out, smaller distribution hubs. This low-cost response directly benefits a business by delivering products much more quickly. Additionally, a 3PL can efficiently manage inventories to quickly scale up or down to meet demand.

- A 4PL can perform the same function as 3PLs in field services, except it employs more advanced, integrative technologies that enable it to optimize all aspects of the supply chain. This includes determining anticipated demands, what products to supply, in what quantities and locations. Deliveries can be managed faster to improve efficiency and maximize customer satisfaction.

Retail/ E-Commerce

- As 3PLs give businesses more flexibility and scalability, they can help develop personalized strategies to improve supply chain management across retail businesses. Many e-commerce businesses choose 3PLs because they provide a good combination of support, flexibility, and cost-effectiveness.

- If a business is servicing a large market with fast-moving parts, materials or products, across multiple warehouses, they need a fast-moving, forward-deployment inventory model that is best served by 4PLs.

By managing the entire supply chain network, a 4PL can allocate inventory to meet customer demand faster. In retail and e-commerce, 4PLs enable companies to provide same-day delivery regardless of location, as well as same-day replenishment.

For more information on how SBT can help your business grow through efficient logistics support and supply-chain methodologies, get in touch with us here.